# Geotextile Non-Woven Fabric: Applications and Benefits in Civil Engineering

Geotextile non-woven fabric has become an essential material in modern civil engineering projects. Its unique properties and versatility make it a go-to solution for a wide range of applications. In this article, we will explore the various uses and advantages of geotextile non-woven fabric in civil engineering.

## What is Geotextile Non-Woven Fabric?

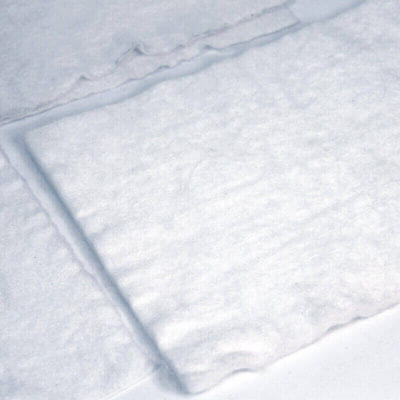

Geotextile non-woven fabric is a synthetic textile material made from polypropylene or polyester fibers. These fibers are bonded together through mechanical, thermal, or chemical processes, creating a durable and permeable fabric. The non-woven structure allows for excellent filtration and drainage properties, making it ideal for civil engineering applications.

## Applications of Geotextile Non-Woven Fabric in Civil Engineering

### 1. Road Construction

One of the primary uses of geotextile non-woven fabric is in road construction. It is commonly used as a separation layer between the subgrade and the base course. This prevents the mixing of different soil layers, ensuring the stability and longevity of the road. Additionally, the fabric’s filtration properties help in draining water away from the road structure, reducing the risk of water damage.

### 2. Erosion Control

Geotextile non-woven fabric is widely used in erosion control applications. It is often employed in slope stabilization, riverbank protection, and coastal defense projects. The fabric helps to retain soil particles while allowing water to pass through, preventing soil erosion and promoting vegetation growth. This makes it an environmentally friendly solution for managing erosion in sensitive areas.

### 3. Landfill Liners and Caps

In landfill engineering, geotextile non-woven fabric is used as a protective layer in liners and caps. It acts as a cushioning material, preventing damage to the geomembrane from sharp objects. The fabric also enhances the drainage system within the landfill, ensuring efficient leachate collection and management. This contributes to the overall safety and environmental performance of landfill sites.

### 4. Drainage Systems

Geotextile non-woven fabric is an integral component of drainage systems in civil engineering projects. It is used in subsurface drainage, retaining wall drainage, and French drains. The fabric’s permeability allows water to flow through while preventing soil particles from clogging the drainage system. This ensures the long-term effectiveness of the drainage infrastructure.

## Benefits of Geotextile Non-Woven Fabric

### 1. Durability

Geotextile non-woven fabric is highly durable and resistant to environmental factors such as UV radiation, chemicals, and biological degradation. This makes it suitable for long-term applications in harsh conditions.

### 2. Cost-Effectiveness

The use of geotextile non-woven fabric can lead to significant cost savings in civil engineering projects. By improving the performance and lifespan of structures, it reduces the need for frequent maintenance and repairs.

### 3. Environmental Protection

Geotextile non-woven fabric plays a crucial role in protecting the environment. Its use in erosion control and landfill applications helps to minimize soil loss and contamination, contributing to sustainable development.

### 4. Versatility

The versatility of geotextile non-woven fabric allows it to be used in a wide range of civil engineering applications. Its adaptability to different project requirements makes it a valuable material for engineers and contractors.

## Conclusion

Geotextile non-woven fabric is a vital material in civil engineering, offering numerous applications and benefits. From road construction to erosion control and landfill management, its unique properties make it an indispensable tool for modern infrastructure projects. As the demand for sustainable and cost-effective solutions continues to grow, geotextile non-woven fabric will undoubtedly remain a key component in the field of civil engineering.

Keyword: geotextile non woven fabric